Test Rack Equipment

200T Test bed

Allows the operator to apply a pulling force of up to 200 Tons

Challenge

Test bed services provided

We at Ogre Engineering Limited have been providing Jar / test bed solution since the beginning, we offer the following:

* On site service / inspection and calibration.

*Supply of components, bearings, hoses, nubbins and test caps, what ever the client requires.

* Basic maintenance and Operator training.

JAR & ACCELERATOR Test Control Console

Designed to test and operate Thru-tubing, Fishing and drilling down-hole tools.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

System Specifications range:

· 240V electric control system

· 17” Touch screen PLC data logging system c/w keyboard

· Full range adjustable hydraulic system pressure.

· User friendly control panel.

· Unit footprint 700 x 600 x 900mm (W x D x H)

The unit is designed to replace all other operating systems to give full control complete with standard operation for the end user. The system will connect to any existing test bed on the market, due to design the unit can be easily installed and calibrated in most cases within one day if all services are made available. The new system has been designed with area location and operator use in mind to keep all components simple, common and operator friendly.

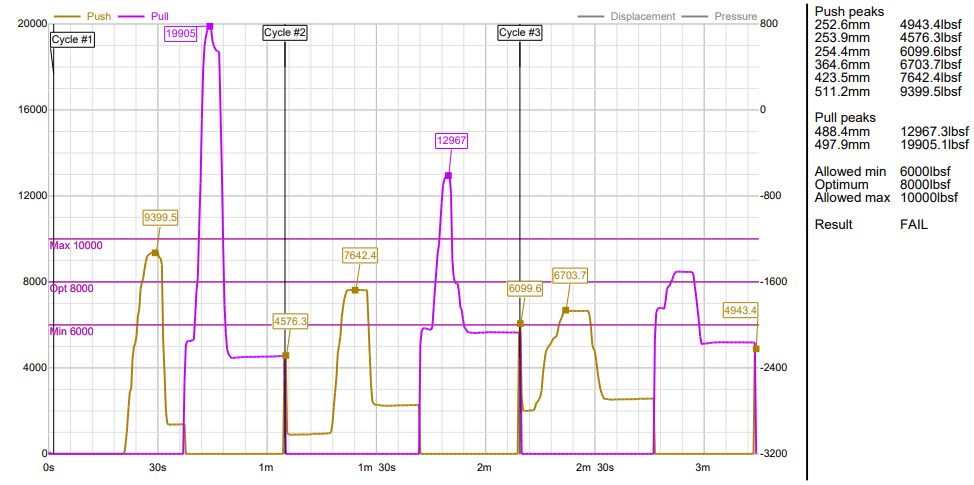

PLC data Logging system

OGRE Engineering Ltd has been working closely with Eztek (Measurement and control) limited for the past 10 years to be the supplier of all their electronic control systems due to their professional service and after sales product support. The PLC unit installed is standard with custom software allowing full flexibility to the client’s requirements.

System Specifications range:

· Simple touch screen operation.

· Windows CE reliable platform.

· 2 Stage graph recording, Force /Time & Force / distance.

· Charts produced in PDF or network format.

· Client Customed graph lay out c/w Client logo.

· Calibration traceable to UKAS standard.

· Panel mounted USB download point.

Intelligent Hydraulics

The unit has been engineered to provide simple servicing and calibration which allows the unit to be located in any environment and designed for simplicity in mind to allow ease of service in remote locations. The “Intelligent Hydraulic” system allows the operator to achieve repeatability through constant flow and pressure in testing tools removing inconsistency in operation.

With each unit there is a full Safety, Operations, Maintenance and Service manual giving all information and certification on the equipment, all equipment is designed and manufactured to the machinery directive.

All equipment manufactured is fully commissioned on-site with the visual reference gauge supplied. It is advised that the unit should be calibrated each year along with a health check and service. Hydraulic pressure gauges can be exchanged with calibrated units should this be required.

Product Model’s available OGRE Engineering Limited has designed the unit to be available in three models:

· Basic – Designed to allow the operator to test equipment, manual operation with no PLC data system, gauge reference only.

· Standard - Designed to allow the operator to test equipment, manual operation with PLC data recording system. Equipment is manufactured to order; delivery is between 8 and 16 weeks depending on model required.

Should any further information be required on the new design equipment please contact our sales department.